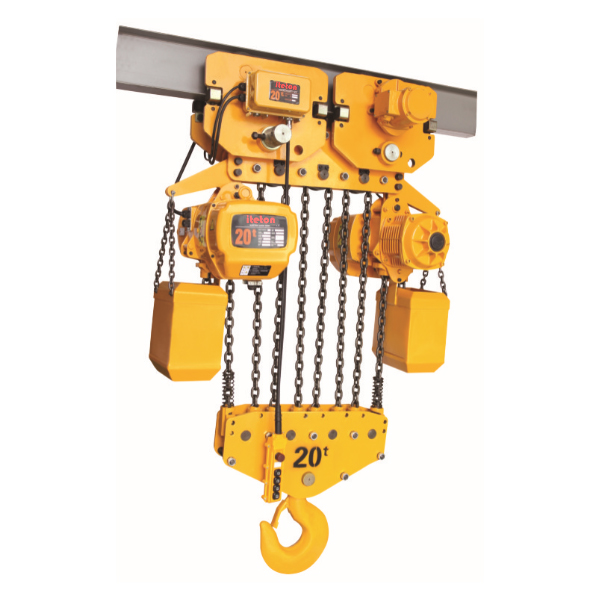

Electric hoist is a kind of special lifting equipment, with small size, light weight, simple operation, easy to use and other characteristics. Our own products have professional metal stamping manufacturers are responsible for the electric hoist shell and structural parts manufacturing. And we have specialized metal casting parts suppliers to provide product parts manufacturing. The hoist often used in industrial and mining enterprises, storage, wharf and other places, the service industry or family lifting heavy lifting is mainly used for small power electric hoist.Electric hoist is generally installed on the overhead i-beam rail or fixed on the frame, lifting a variety of heavy objects.

I’ll share a few tips for installing electric hoists here:

- When opening the electric hoist package, the main engine and other relevant parts are disassembled and placed separately.

Therefore, before installation, it is necessary to check whether each part has been damaged and confirm that the parts are normal before installation.

In addition, before installation, the electric hoist reducer needs to be oiled. - After the suspension electric hoist is assembled, a gap of 3-5mm is left between the edge of the running wheel and the lower edge of the i-beam track when it is installed on the i-beam track. The gap can be adjusted by a washer on the bolt.

- Check whether the limit block used to fix the wire rope is installed securely, and add the rope clip as required.

- After the electric hoist is installed and connected, lift the empty hook to the top limit position to ensure a sufficient distance between the top position and the shell of the hoist. Then adjust and tighten the top limit stop block.

Drop the hook to the bottom limit position, ensure that there are still 2 or 3 rings of steel wire on the hoist reel, adjust and tighten the bottom limit stop block. - To ensure that the hoist can run normally to both ends of the track without derailment or collision, stop blocks and buffer devices should be set at both ends of the track.

- The two ends of the i-beam track or its connected bracket shall be connected to a ground wire to prevent electricity leakage.

- Electric hoist on any position of grounding resistance shall not be greater than 0.1 Ω (ground wire can use 4-5 mm² copper wire or not less than 25 mm² metal conductor).

Want to learn more about lifting equipment installation techniques and matters needing attention, please store up and contact us:

Email: info@iteton-machinery.com

Tel: +86-23-68623758

WhatsApp/ Wechat:+86 15025409479

Address: 2-30-9, No.6, Xingyan Road, Jiulongpo District, Chongqing, China

Leave A Comment